Dye Intermediates

300 INR/Kilograms

Product Details:

- Shelf Life 2 years minimum if stored properly

- Purity 98% min (may vary)

- Rubbing Resistance High

- Poisonous May be toxic, refer to MSDS

- Resistance Good to solvents and chemicals

- Strength High pigment/dye strength

- Melting Point Depends on compound, typically 70-130°C

- Click to View more

X

Dye Intermediates Price And Quantity

- 300 INR/Kilograms

- 50 Kilograms

Dye Intermediates Product Specifications

- Characteristic to each chemical

- 1.5 Gram per cubic centimeter(g/cm3)

- Soluble in water and organic solvents

- Varies by intermediate

- Crystalline / Powdered / Granular

- Variable, depends on the specific intermediate

- Industrial grade

- Dyestuff, pigment, textile, pharmaceutical, agro chemicals

- High pigment/dye strength

- Good to solvents and chemicals

- Good

- Depends on compound, typically 70-130°C

- High

- May be toxic, refer to MSDS

- Depends on compound

- Dye Chemical Intermediates

- Powder / Crystal / Granules depending on type

- Pale to deep depending on type

- 98% min (may vary)

- 2 years minimum if stored properly

- <1.0%

- Synthetic Organic Chemicals

- Varies by intermediate

- Intermediate for dye manufacturing

- 20-500 mesh, as specified

- 2821, 2921, 3204 etc. (varies with specific intermediate)

- Slightly acidic to neutral (5-7)

- Variable, as per product

Dye Intermediates Trade Information

- 1000 Kilograms Per Month

- 1 Week

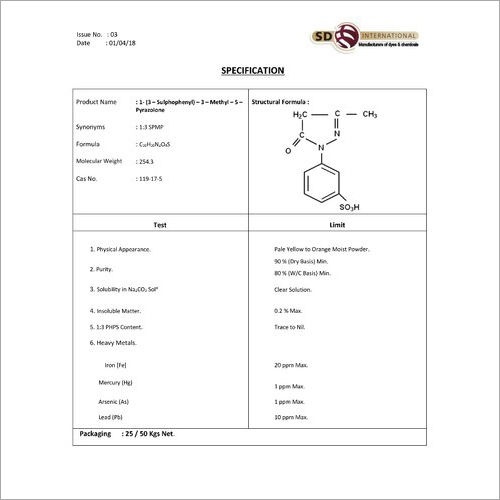

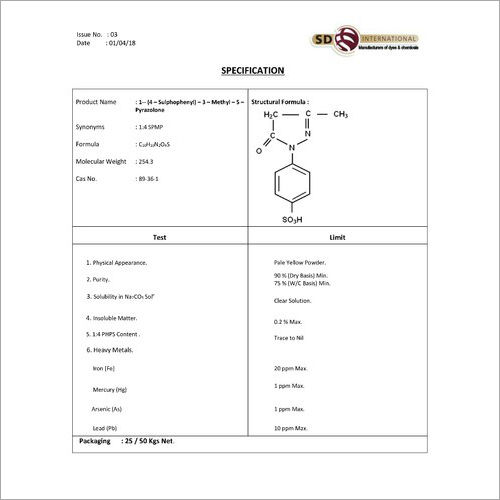

Product Description

Dye Intermediates are applicable for the industries of Paints, Printing Inks, Plastics, Paper, Textiles, Hair Dyes etc. This is included with petroleum downstream products, suited for the transformation to finished pigments and dyes. Dye Intermediates are the useful for different industry sectors such as paints, textiles, plastics, printing inks, paper. Dye Intermediates are popular as the important raw materials for Direct/Acid and Reactive colors. Also, these are used in making hair dyes as well as others.

| Packaging Size | 1 kg |

| Form | Powder |

| Brand | SD International |

| Usage/Application | industries like textiles, plastics, paints, printing inks and paper. |

| Place of origin | India |

| Country of Origin | Made in India |

Reliable Intermediates for Dye Manufacturing

Our Dye Intermediates are crafted with industrial standards in mind, offering a minimum purity of 98%. With variable physical forms and appearances, they integrate seamlessly into dye, pigment, and specialty chemical production processes. Each batch is securely packaged to maintain product integrity and can be tailored to specific size and form requirements. Suitable for exporters, importers, manufacturers, and suppliers, these intermediates help ensure vibrant colors and strong performance.

Safety, Storage, and Quality Assurance

To maintain quality, Dye Intermediates should be stored in airtight containers away from moisture and direct sunlight. While generally non-hazardous for transport, customers are advised to consult the specific MSDS for correct hazard classification and handling protocols. With a shelf life of at least two years under proper storage, users benefit from durable chemical stability and high reliability.

FAQs of Dye Intermediates:

Q: How should Dye Intermediates be stored to maintain their quality?

A: Dye Intermediates should be kept in airtight containers, away from moisture and direct sunlight, to preserve their chemical stability and ensure a shelf life of at least two years.Q: What are the primary uses of Dye Intermediates in industry?

A: They are principally used as intermediates in dye manufacturing, but also find applications in the pigment, textile, pharmaceutical, and agrochemical sectors.Q: When can customization of Dye Intermediates be requested?

A: Customisation in terms of physical form, mesh size, packaging, and specific purity levels can be requested at the time of placing an order to meet client-specific manufacturing needs.Q: Where can Dye Intermediates be delivered and in what packaging options?

A: They can be shipped globally in 25 kg or 50 kg HDPE bags with liners, or customized packaging as required by clients.Q: What benefits do Dye Intermediates provide in manufacturing processes?

A: They offer high pigment strength, good resistance to solvents and chemicals, excellent water and rubbing resistance, and consistent quality, enhancing the performance of finished products.Q: What is the minimum order quantity for purchasing Dye Intermediates?

A: The minimum order quantity for this product is 500 kg per shipment, allowing for bulk and scalable industrial use.Q: How is the safety of Dye Intermediates ensured during transport?

A: These intermediates are classified as non-hazardous for transportation but it is essential to verify specific hazard status with the corresponding MSDS for each type.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free